Page 79 - Gaylord Blue Book 2021

P. 79

DCV-AV AirVantage

ITEM NO. _______________

MODEL AirVantage (DCV-AV)

DEMAND CONTROL VENTILATION

WITH SMART READ AND REACT TECHNOLOGY

FOR MULTIPLE HOOD SINGLE FAN EXHAUST SYSTEMS

GENERAL SPECIFICATIONS AND DESCRIPTION

Furnish Gaylord Demand Control Ventilation (DCV) with smart read and

react technology Model “DCV-AV” (AirVantage) as shown on plans and in

accordance with the following specifications:

DCV-AV AIRVANTAGE SYSTEM DESCRIPTION: The purpose of the 7

DCV-AV (AirVantage) system is to reduce kitchen operational and util-

ity costs by conserving energy through the reduction of exhaust and

makeup air for the commercial kitchen ventilation (CKV) system while ef- 7

fectively communicating with the Building Management System (BMS). 7 3

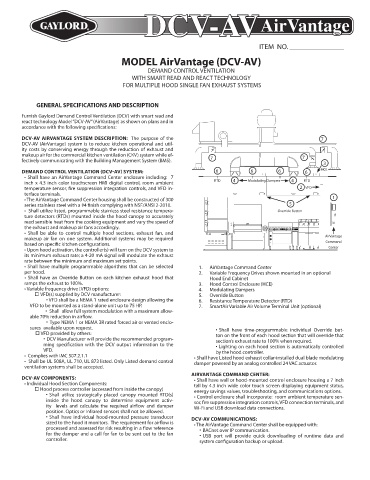

DEMAND CONTROL VENTILATION (DCV-AV) SYSTEM: 6 6 6 6 HCE

• Shall have an AirVantage Command Center enclosure including: 7

inch x 4.3 inch color touchscreen HMI digital control, room ambient RTD 4 Modulating Dampers 4 RTD

temperature sensor, fire suppression integration controls, and VFD in- 2 VFD

terface terminals.

• The AirVantage Command Center housing shall be constructed of 300 1

series stainless steel with a #4 finish complying with NSF/ANSI 2-2010. 5

• Shall utilize listed, programmable stainless steel resistance tempera- Override Button

ture detectors (RTDs) mounted inside the hood canopy to accurately

read sensible heat from the cooking equipment and vary the speed of

the exhaust and makeup air fans accordingly.

• Shall be able to control multiple hood sections, exhaust fan, and

makeup air fan on one system. Additional systems may be required AirVantage

based on specific kitchen configurations. Command

• Upon hood activation, the controller(s) will turn on the DCV system to Center

its minimum exhaust rate; a 4-20 mA signal will modulate the exhaust

rate between the minimum and maximum set points.

• Shall have multiple programmable algorithms that can be selected 1. AirVantage Command Center

per hood. 2. Variable Frequency Drives shown mounted in an optional

• Shall have an Override Button on each kitchen exhaust hood that Hood End Cabinet

ramps the exhaust to 100%. 3. Hood Control Enclosure (HCE)

• Variable frequency drive (VFD) options: 4. Modulating Dampers

VFD(s) supplied by DCV manufacturer: 5. Override Button

VFD shall be a NEMA 1 rated enclosure design allowing the 6. Resistance Temperature Detector (RTD)

VFD to be mounted as a stand-alone unit up to 75 HP. 7. SmartAir Variable Air Volume Terminal Unit (optional)

Shall allow full system modulation with a maximum allow-

able 70% reduction in airflow.

Type NEMA 1 or NEMA 3R rated forced air or vented enclo-

sures available upon request. Shall have time-programmable individual Override but-

VFD provided by others: ton on the front of each hood section that will override that

DCV Manufacturer will provide the recommended program- section’s exhaust rate to 100% when required.

ming specification with the DCV output information to the Lighting on each hood section is automatically controlled

VFD. by the hood controller.

• Complies with IMC 507.2.1.1 • Shall have Listed hood exhaust collar-installed dual blade modulating

• Shall be UL 508A, UL 710, UL 873 listed. Only Listed demand control damper powered by an analog controlled 24 VAC actuator.

ventilation systems shall be accepted.

AIRVANTAGE COMMAND CENTER:

DCV-AV COMPONENTS: • Shall have wall or hood-mounted control enclosure housing a 7 inch

• Individual Hood Section Components: tall by 4.3 inch wide color touch screen displaying equipment status,

Hood process controller (accessed from inside the canopy) energy savings values, troubleshooting, and communications options.

Shall utilize strategically placed canopy mounted RTD(s) • Control enclosure shall incorporate: room ambient temperature sen-

inside the hood canopy to determine equipment activ- sor, fire suppression integration controls, VFD connection terminals, and

ity levels and calculate the required airflow and damper Wi-Fi and USB download data connections.

position. Optics or Infrared sensors shall not be allowed.

Shall have individual hood-mounted pressure transducer DCV-AV COMMUNICATIONS:

sized to the hood it monitors. The requirement for airflow is • The AirVantage Command Center shall be equipped with:

processed and assessed for risk resulting in a flow reference BACnet over IP communication.

for the damper and a call for fan to be sent out to the fan USB port will provide quick downloading of runtime data and

controller. system configuration backup or upload.