Page 36 - Gaylord Blue Book 2021

P. 36

ELX SERIES

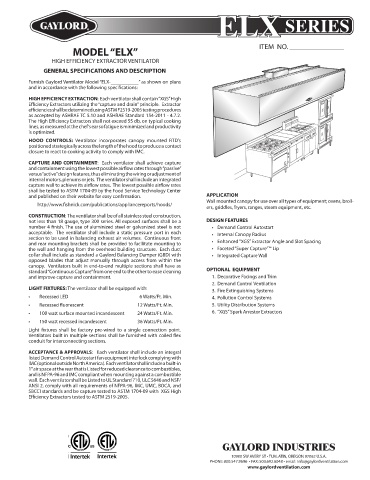

MODEL “ELX” ITEM NO. _______________

HIGH EFFICIENCY EXTRACTOR VENTILATOR

GENERAL SPECIFICATIONS AND DESCRIPTION

Furnish Gaylord Ventilator Model “ELX-___________” as shown on plans

and in accordance with the following specifications:

HIGH EFFICIENCY EXTRACTION: Each ventilator shall contain “XGS” High

Efficiency Extractors utilizing the “capture and drain” principle. Extractor

efficiencies shall be determined using ASTM F2519-2005 testing procedures

as accepted by ASHRAE TC 5.10 and ASHRAE Standard 154-2011 - 4.7.2.

The High Efficiency Extractors shall not exceed 55 db, on typical cooking

lines, as measured at the chef’s ear so fatigue is minimized and productivity

is optimized.

HOOD CONTROLS: Ventilator incorporates canopy mounted RTD’s

positioned strategically across the length of the hood to produce a contact

closure to react to cooking activity to comply with IMC.

CAPTURE AND CONTAINMENT: Each ventilator shall achieve capture

and containment using the lowest possible airflow rates through “passive”

versus “active” design features, thus eliminating the wiring or adjustment of

internal motors, plenums or jets. The ventilator shall include an integrated

capture wall to achieve its airflow rates. The lowest possible airflow rates

shall be tested to ASTM 1704-09 by the Food Service Technology Center

and published on their website for easy confirmation. APPLICATION

http://www.fishnick.com/publications/appliancereports/hoods/ Wall mounted canopy for use over all types of equipment; ovens, broil-

ers, griddles, fryers, ranges, steam equipment, etc.

CONSTRUCTION: The ventilator shall be of all stainless steel construction,

not less than 18 gauge, type 300 series. All exposed surfaces shall be a DESIGN FEATURES

number 4 finish. The use of aluminized steel or galvanized steel is not • Demand Control Autostart

acceptable. The ventilator shall include a static pressure port in each • Internal Canopy Radius

section to be used in balancing exhaust air volumes. Continuous front

and rear mounting brackets shall be provided to facilitate mounting to • Enhanced “XGS” Extractor Angle and Slot Spacing

the wall and hanging from the overhead building structure. Each duct • Faceted “Super Capture”™ Lip

collar shall include as standard a Gaylord Balancing Damper (GBD) with • Integrated Capture Wall

opposed blades that adjust manually through access from within the

canopy. Ventilators built in end-to-end multiple sections shall have as

standard “Continuous Capture” from one end to the other to ease cleaning OPTIONAL EQUIPMENT

and improve capture and containment. 1. Decorative Facings and Trim

2. Demand Control Ventilation

LIGHT FIXTURES: The ventilator shall be equipped with: 3. Fire Extinguishing Systems

• Recessed LED 6 Watts/Ft. Min. 4. Pollution Control Systems

• Recessed fluorescent 12 Watts/Ft. Min. 5. Utility Distribution Systems

• 100 watt surface mounted incandescent 24 Watts/Ft. Min. 6. “XGS” Spark Arrestor Extractors

• 150 watt recessed incandescent 36 Watts/Ft. Min.

Light fixtures shall be factory pre-wired to a single connection point.

Ventilators built in multiple sections shall be furnished with coiled flex

conduit for interconnecting sections.

ACCEPTANCE & APPROVALS: Each ventilator shall include an integral

listed Demand Control Autostart fan equipment interlock complying with

IMC (optional outside North America). Each ventilator shall include a built-in

1” air space at the rear that is Listed for reduced clearance to combustibles,

and is NFPA-96 and IMC compliant when mounting against a combustible

wall. Each ventilator shall be Listed to UL Standard 710, ULC S646 and NSF/

ANSI 2, comply with all requirements of NFPA-96, IMC, UMC, BOCA, and

SBCCI standards and be capture tested to ASTM 1704-09 with XGS High

Efficiency Extractors tested to ASTM 2519-2005.

GAYLORD INDUSTRIES

10900 SW AVERY ST • TUALATIN, OREGON 97062 U.S.A.

PHONE: 800.547.9696 • FAX: 503.692.6048 • email: info@gaylordventilation.com

www.gaylordventilation.com