Page 73 - Gaylord Blue Book 2021

P. 73

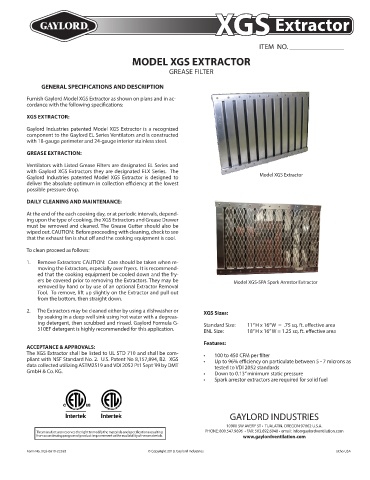

XGS Extractor

ITEM NO. _______________

MODEL XGS EXTRACTOR

GREASE FILTER

GENERAL SPECIFICATIONS AND DESCRIPTION

Furnish Gaylord Model XGS Extractor as shown on plans and in ac-

cordance with the following specifications:

XGS EXTRACTOR:

Gaylord Industries patented Model XGS Extractor is a recognized

component to the Gaylord EL Series Ventilators and is constructed

with 18-gauge perimeter and 24-gauge interior stainless steel.

GREASE EXTRACTION:

Ventilators with Listed Grease Filters are designated EL Series and

with Gaylord XGS Extractors they are designated ELX Series. The

Gaylord Industries patented Model XGS Extractor is designed to Model XGS Extractor

deliver the absolute optimum in collection efficiency at the lowest

possible pressure drop.

DAILY CLEANING AND MAINTENANCE:

At the end of the each cooking day, or at periodic intervals, depend-

ing upon the type of cooking, the XGS Extractors and Grease Drawer

must be removed and cleaned. The Grease Gutter should also be

wiped out. CAUTION: Before proceeding with cleaning, check to see

that the exhaust fan is shut off and the cooking equipment is cool.

To clean proceed as follows:

1. Remove Extractors: CAUTION: Care should be taken when re-

moving the Extractors, especially over fryers. It is recommend-

ed that the cooking equipment be cooled down and the fry-

ers be covered prior to removing the Extractors. They may be Model XGS-SPA Spark Arrestor Extractor

removed by hand or by use of an optional Extractor Removal

Tool. To remove, lift up slightly on the Extractor and pull out

from the bottom, then straight down.

2. The Extractors may be cleaned either by using a dishwasher or XGS Sizes:

by soaking in a deep well sink using hot water with a degreas-

ing detergent, then scrubbed and rinsed. Gaylord Formula G- Standard Size: 11” H x 16”W = .75 sq. ft. effective area

510EF detergent is highly recommended for this application. ENL Size: 18” H x 16” W = 1.25 sq. ft. effective area

Features:

ACCEPTANCE & APPROVALS:

The XGS Extractor shall be listed to UL STD 710 and shall be com- • 100 to 450 CFM per filter

pliant with NSF Standard No. 2. U.S. Patent No 8,157,894, B2. XGS • Up to 96% efficiency on particulate between 5 - 7 microns as

data collected utilizing ASTM2519 and VDI 2052 Pt1 Sept ‘99 by DMT tested to VDI 2052 standards

GmbH & Co. KG. • Down to 0.13” minimum static pressure

• Spark arrestor extractors are required for solid fuel

GAYLORD INDUSTRIES

10900 SW AVERY ST • TUALATIN, OREGON 97062 U.S.A.

The manufacturer reserves the right to modify the materials and specifications resulting PHONE: 800.547.9696 • FAX: 503.692.6048 • email: info@gaylordventilation.com

from a continuing program of product improvement or the availability of new materials. www.gaylordventilation.com

Form No. XGS-0619-22392 © Copyright 2019, Gaylord Industries Litho USA