Page 68 - Gaylord Blue Book 2021

P. 68

ELXC SERIES

SMOKE CONTROL SECTION CONTINUED: LIGHT FIXTURES: The ventilator shall be equipped with:

40 to 80 PSI at a minimum of 120°F and a maximum of 140°F. An electric o Recessed LED 10 Watts/Ft. Min.

booster heater will be supplied with the GPC-7000SPC control cabinet to

increase this to 160°F to 180°F. The booster will require a 230 volt 3-phase

40 amp minimum connection and the electrical requirement varies on Canopy mounted LED light fixtures provide 50 foot candles at the cooking

model selected. Maximum water flow rate for the ESP section is not to surface and shall be factory pre-wired to a single connection point.

Ventilators built in multiple sections shall be furnished with coiled flex

exceed 8 GPM. The ESP cell section shall have a 2” drain with a motorized conduit for interconnecting sections.

ball valve that closes when the wash system is off to prevent air bypassing

the grease extractors in the hood. This drain shall connect to an approved

grease trap prior to entering the sewer system. ACCEPTANCE & APPROVALS: Each ventilator shall include a listed Demand

Control Autostart, fan equipment interlock, complying with IMC (optional

outside North America). Each ventilator shall include a built-in 1” air space

CONSTRUCTION: Each ventilator section shall include non-gasketed and

non-removable full length access panels to ease inspection of extractors, at the rear that is Listed for reduced clearance to combustibles, and is

secondary filters, UV lamps, plenum and fire extinguishing system. The ESP NFPA-96 and IMC compliant when mounting against a combustible wall.

section shall be mounted, sealed and accessible from inside the hood’s Each ventilator shall be Listed to UL Standard 710 and 710C, ULC S646, UL

canopy by gasketed access panels with keyed lift and turn latches. The 867 and NSF/ANSI 2, comply with all requirements of NFPA-96, IMC, UMC,

BOCA, and SBCCI standards.

ventilator shall be of all stainless steel construction, not less than 18 gauge,

type 300 series. All exposed surfaces shall be a number 4 finish. The use of

aluminized steel or galvanized steel is not acceptable. Continuous front and

rear mounting brackets shall be provided to facilitate mounting to the wall

and hanging from the overhead building structure. Minimum ventilator

length is 6’ and can be built in multiple sections for longer applications.

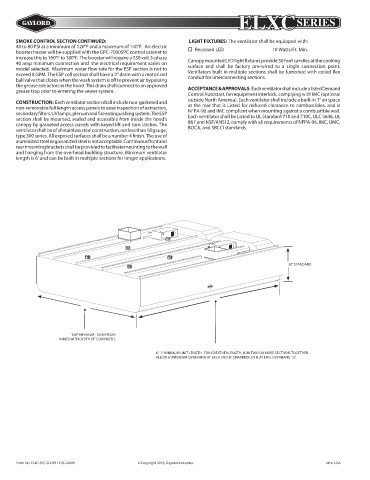

30” STANDARD

148” MINIMUM - DIMENSION

VARIES WITH DEPTH OF EQUIPMENT.

6’- 1” MINIMUM UNIT LENGTH. FOR GREATHER LENGTH, JOIN TWO OR MORE SECTIONS TOGETHER.

ALLOW 6” MINIMUM OVERHANG AT EACH END. IF CHARBROILER IS AT END, OVERHANG 12”.

Form No. ELXC-SPC-SO-BB 1218-22699 © Copyright 2018, Gaylord Industries Litho USA