Page 87 - Gaylord Blue Book 2021

P. 87

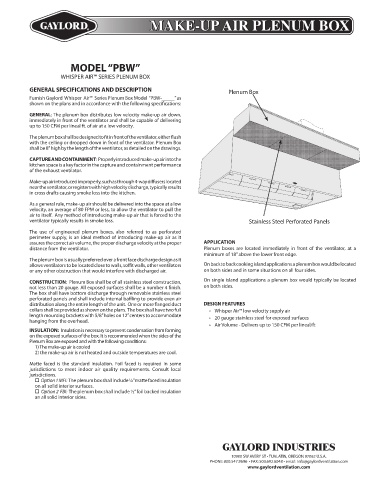

MAKE-UP AIR PLENUM BOX

MODEL “PBW”

WHISPER AIR™ SERIES PLENUM BOX

GENERAL SPECIFICATIONS AND DESCRIPTION Plenum Box

Furnish Gaylord Whisper Air™ Series Plenum Box Model “PBW-_____” as

shown on the plans and in accordance with the following specifications:

GENERAL: The plenum box distributes low velocity make-up air down,

immediately in front of the ventilator and shall be capable of delivering

up to 150 CFM per lineal ft. of air at a low velocity.

The plenum box shall be designed to fit in front of the ventilator, either flush

with the ceiling or dropped down in front of the ventilator. Plenum Box

shall be 8" high by the length of the ventilator, as detailed on the drawings.

CAPTURE AND CONTAINMENT: Properly introduced make-up air into the

kitchen space is a key factor in the capture and containment performance

of the exhaust ventilator.

Make-up air introduced improperly, such as through 4-way diffusers located

near the ventilator, or registers with high velocity discharge, typically results

in cross drafts causing smoke loss into the kitchen.

As a general rule, make-up air should be delivered into the space at a low

velocity, an average of 80 FPM or less, to allow the ventilator to pull the

air to itself. Any method of introducing make-up air that is forced to the

ventilator typically results in smoke loss. Stainless Steel Perforated Panels

The use of engineered plenum boxes, also referred to as perforated

perimeter supply, is an ideal method of introducing make-up air as it

assures the correct air volume, the proper discharge velocity at the proper APPLICATION

distance from the ventilator. Plenum boxes are located immediately in front of the ventilator, at a

minimum of 18” above the lower front edge.

The plenum box is usually preferred over a front face discharge design as it

allows ventilators to be located close to walls, soffit walls, other ventilators On back to back cooking island applications a plenum box would be located

or any other obstruction that would interfere with discharged air. on both sides and in some situations on all four sides.

CONSTRUCTION: Plenum Box shall be of all stainless steel construction, On single island applications a plenum box would typically be located

not less than 20 gauge. All exposed surfaces shall be a number 4 finish. on both sides.

The box shall have bottom discharge through removable stainless steel

perforated panels and shall include internal baffling to provide even air

distribution along the entire length of the unit. One or more flanged duct DESIGN FEATURES

collars shall be provided as shown on the plans. The box shall have two full • Whisper Air™ low velocity supply air

length mounting brackets with 5/8” holes on 12” centers to accommodate • 20 gauge stainless steel for exposed surfaces

hanging from the overhead.

• Air Volume - Delivers up to 150 CFM per lineal/ft

INSULATION: Insulation is necessary to prevent condensation from forming

on the exposed surfaces of the box. It is recommended when the sides of the

Plenum Box are exposed and with the following conditions:

1) The make-up air is cooled

2) the make-up air is not heated and outside temperatures are cool.

Matte faced is the standard insulation. Foil faced is required in some

jurisdictions to meet indoor air quality requirements. Consult local

jurisdictions.

o Option 1 MFI: The plenum box shall include ½” matte faced insulation

on all solid interior surfaces.

o Option 2 FBI: The plenum box shall include ½” foil backed insulation

an all solid interior sides.

GAYLORD INDUSTRIES

10900 SW AVERY ST • TUALATIN, OREGON 97062 U.S.A.

PHONE: 800.547.9696 • FAX: 503.692.6048 • email: info@gaylordventilation.com

www.gaylordventilation.com