Page 92 - Gaylord Blue Book 2021

P. 92

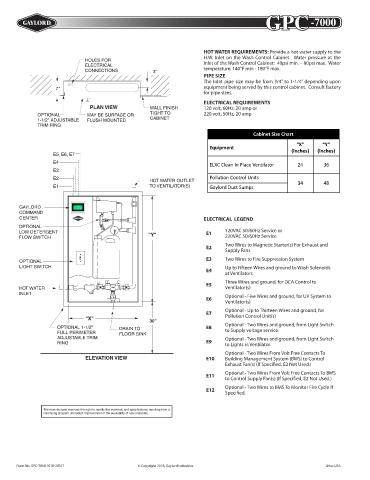

GPC -7000

GPC -6000-D

HOT WATER REQUIREMENTS: Provide a hot water supply to the

H.W. Inlet on the Wash Control Cabinet. Water pressure at the

inlet of the Wash Control Cabinet: 40psi min. – 80psi max. Water

HOT WATER REQUIREMENTS

temperature: 140°F min - 180°F max.

Equipment PIPE SIZE Temp (°F) Pressure (PSI)

The Inlet pipe size may be from 3/4” to 1-1/4” depending upon

Water Wash Ventilator or 140 min. 40 min.

equipment being served by this control cabinet. Consult factory

Water Wash Ventilator w/ UV 180 max. 80 max.

for pipe sizes.

Water Wash Ventilator w/ UV 140 min. 60 min.

and Pollution Control 180 max. 80 max.

ELECTRICAL REQUIREMENTS

120 volt, 60Hz, 20 amp or 30 min.

140 min.

Pollution Control Units 180 max. 80 max.

220 volt, 50Hz, 20 amp

140 min. 40 min.

Gaylord Duct Sumps

180 max. 80 max.

PIPE SIZE Cabinet Size Chart

The Inlet pipe size may be from 3/4” to 1-1/2” depending upon

“X”

equipment being served by this control cabinet. Consult factory “Y”

Equipment

for pipe sizes. (Inches) (Inches)

ELECTRICAL REQUIREMENTS

120 volt, 60Hz, 20 amp Non-Interrupted Service or 24 36

ELXC Clean In Place Ventilator

220 volt, 50Hz, 20 amp Non-Interrupted Service

CABINET SIZE CART

Pollution Control Units

HOT WATER OUTLET 34 48

TO VENTILATOR(S) NUMBER ”X” “Y”

OF Gaylord Duct Sumps

SEQUENCES Inches Inches

1-5 - Pipe Size = 1¼” Max.

GAYLORD 1-4 - Pipe Size = 1½” Max. 34 48

COMMAND

CENTER 5 - Pipe Size = 1½” Max. 40 48

ELECTRICAL LEGEND

OPTIONAL NOTES:

120VAC 50/60Hz Service or

LOW DETERGENT A. Consult Factory for Cabinets with more than 5 Sequences

E1

220VAC 50/60Hz Service

FLOW SWITCH B. Add 6” to the “X” Dimension if Cold Water Mist is added.

Consult Factory for Cold Water Mist information.

Two Wires to Magnetic Starter(s) For Exhaust and

E2

ELECTRICAL LEGEND Supply Fans

Two Wires to Fire Suppression System

E3

120VAC 50/60Hz Non-Interrupted Service or

OPTIONAL E1 220VAC 50/60Hz Non-Interrupted Service

LIGHT SWITCH E4 Up to Fifteen Wires and ground to Wash Solenoids

at Ventilators

E2 Two Wires to Magnetic Starter(s) For Exhaust and

Supply Fans

H.W. INLET E3 Two Wires to Fire Suppression System

Three Wires and ground, for DCA Control to

E5

HOT WATER Ventilator(s)

INLET Five Wires and ground to the First Ventilator and

Optional - Five Wires and ground, for UV System to

E4 them Five Wires from Each Ventilator Group to the

E6

Next Ventilator Group

Ventilator(s)

E5 Two Wires and ground, for “Autostart” to Ventilator(s)

Optional - Up to Thirteen Wires and ground, for

18” E7

Pollution Control Unit(s)

Optional - Five Wires and ground, for UV System to

DRAIN TO 30” E6 Ventilator(s)

FLOOR SINK Optional - Two Wires and ground, from Light Switch

E8

DRAIN TO E7 Optional - Up to Thirteen Wires and ground, for

to Supply voltage service.

FLOOR SINK Pollution Control Unit(s)

Optional - Two Wires and ground, from Light Switch

E9

Optional - Two Wires and ground, from Light Switch

E8 to Lights in Ventilator.

ELEVATION VIEW to Supply voltage service.

Optional - Two Wires From Volt Free Contacts To

Optional - Two Wires and ground, from Light Switch

ELEVATION VIEW E9 to Lights in Ventilator.

E10

Building Management System (BMS) to Control

Exhaust Fan(s) (If Specified, E2 Not Used.)

Optional - Two Wires From Volt Free Contacts To

E10 Building Management System (BMS) to Control

Optional - Two Wires From Volt Free Contacts To BMS

E11

Exhaust Fan(s) (If Speci ed, E2 Not Used.)

The manufacturer reserves the right to modify the materials and specifications resulting from a to Control Supply Fan(s) (If Specified, E2 Not Used.)

continuing program of product improvement or the availability of new materials.

E11 Optional - Two Wires From Volt Free Contacts To BMS

Optional - Two Wires to BMS To Monitor Fire Cycle If

to Control Supply Fan(s) (If Speci ed, E2 Not Used.)

E12

Specified.

Optional - Two Wires to BMS To Monitor Fire Cycle If

E12

Speci ed.

The manufacturer reserves the right to modify the materials and specifications resulting from a

continuing program of product improvement or the availability of new materials.

Form No. GPC-6000-D 0410-20233 © Copyright 2010, Gaylord Industries Litho USA

Form No. GPC-7000 1018-20371 © Copyright 2018, Gaylord Industries Litho USA